TEAM THERMOFORMINGS AND ALLIEDS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEAM THERMOFORMINGS AND ALLIEDS

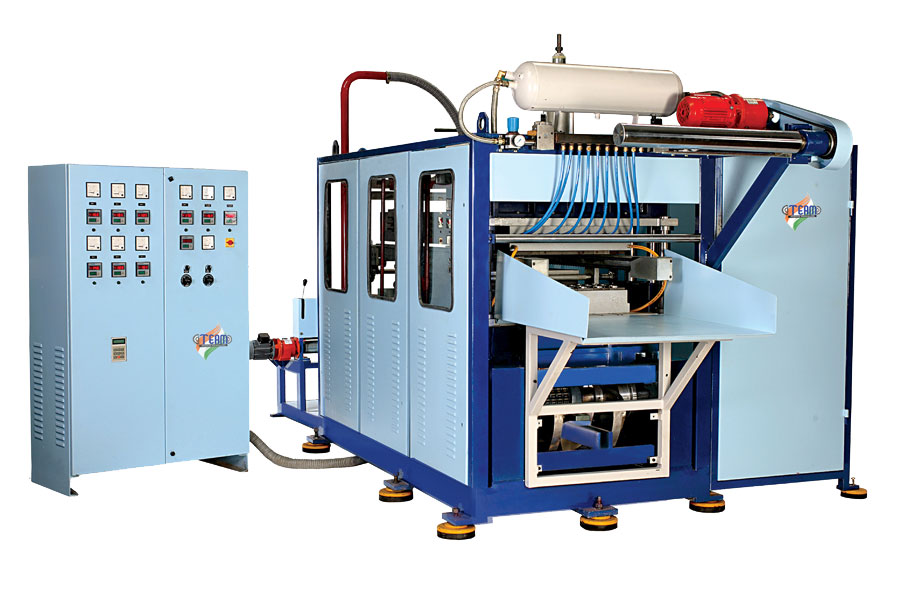

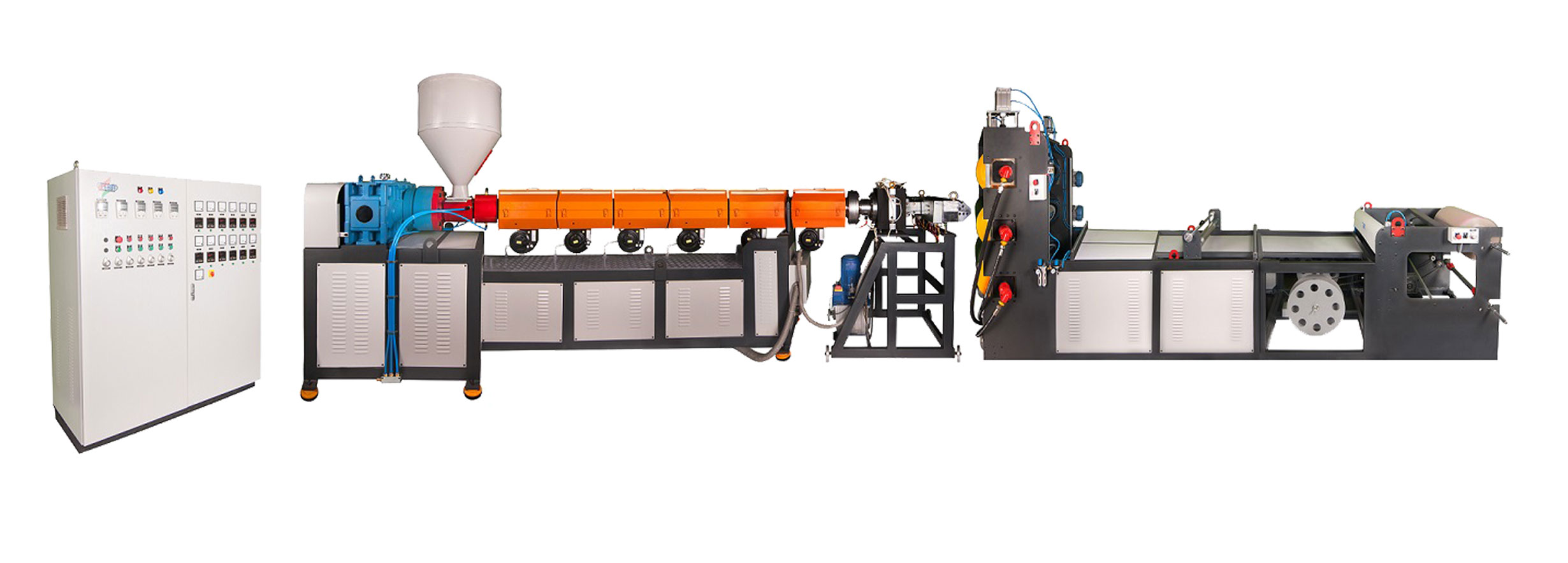

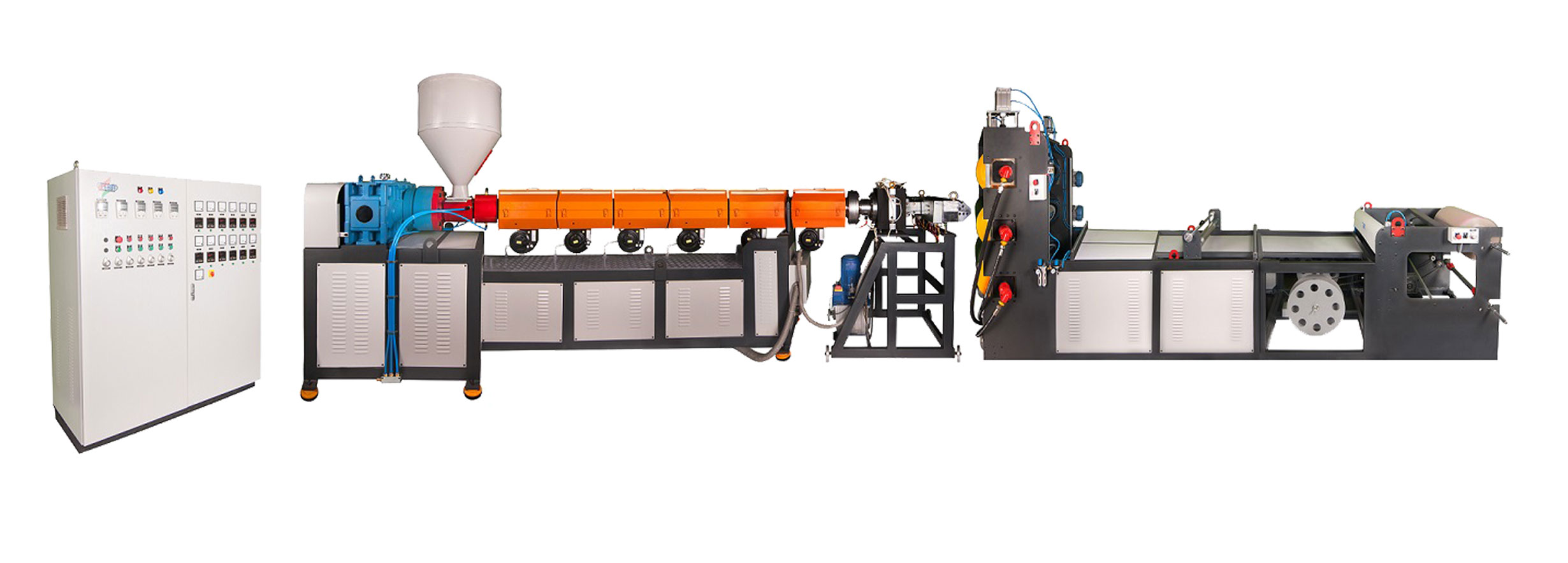

Sheet Extrusion Line

The machine is used for manufacturing plastic sheets of PP, PS, HIPS, etc.

The sheet-line machine is a combination of extruder, calendar, winder and electric control console.

The screw and barrel are made of high quality alloy steel EN- 41 B with optimum hardness and strong corrosion resistance.

The roughness spectrum of rollers range from high mirror gloss surfaces with a roughness value up to Rmax < 0.3 µm.

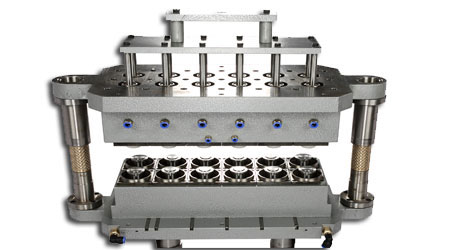

The Vertical 3-Roll Calendar Unit Is Assembled On A Robust Support Frame. Polish Rolls Are Made Of Hardened Alloy Steel. It Is Provided With A Helicoidally Controlled Internal Cooling Chamber For Circulation Of Thermo-Regulated Cooling Fluid.The Dies Are Designed With Rheological Properties On CAD Systems. These Chrome Plated Dies With Polished Flow Surfaces Are Made Of Corrosion Proof Forged Alloy Steel. They Incorporate Rectangular Section Inlets For Multi-Layer Sheets And Flexible Lip Outlet To Control Thickness Perfectly.

On Offer Are Single And Multi-Layer Co-Extrusion Feed Blocks Up To Three Layers With Provision To Adjust The Melt Flow. Uniquely Designed Screen Changer Reduces Residual Time And Pressure Loss. It Also Keeps The Flow Channel Rheological.Hydraulically Operated Continuous Screen Changers Are Also Offered As Optionals.

The Dies Are Designed With Rheological Properties On CAD Systems. These Chrome Plated Dies With Polished Flow Surfaces Are Made Of Corrosion Proof Forged Alloy Steel. They Incorporate Rectangular Section Inlets For Multi-Layer Sheets And Flexible Lip Outlet To Contact Thickness Perfectly.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.